The breathability of sunscreen fabrics is influenced by several factors, and achieving a balance between UV protection and breathability is crucial for comfort and functionality. Here are some key factors:

Fabric Type: Natural fibers, such as cotton and linen, boast inherent breathability owing to their porous structure, allowing for efficient air circulation.

Conversely, synthetic fibers like polyester, while effective in UV protection, may exhibit lower breathability. A strategic blend of natural and synthetic fibers can be employed to optimize both UV protection and breathability.

Fabric Density: Fabric density, determined by the number of yarns per unit area, directly influences UV protection. Higher density typically enhances UV protection but may come at the expense of breathability.

Achieving the desired balance involves a meticulous optimization of fabric density, ensuring effective UV protection without unduly impeding airflow.

Weave Structure: Open weave structures, such as plain weaves or knits, foster improved breathability by creating spaces between fibers. However, a delicate equilibrium must be maintained to preserve UV protection effectiveness.

Tighter weaves, like twills or satins, can heighten UV protection but may compromise breathability. Crafting specific weave patterns becomes instrumental in addressing this inherent trade-off.

Fabric Finishings and Treatments: Finishes like water-resistant or moisture-wicking treatments can wield a pronounced impact on breathability by altering the fabric's interaction with moisture.

The judicious selection and application of finishes become imperative to enhance or maintain breathability while ensuring the intended level of UV protection is sustained.

Innovative Textile Technologies: Cutting-edge advancements, such as microventilation systems, intricately embed breathable components within the fabric structure, facilitating optimal air circulation while upholding UV protection.

Manufacturers engage in continuous research and development to explore and integrate state-of-the-art technologies, elevating overall fabric performance and comfort.

Microfiber Technology: Microfiber fabrics, characterized by exceptionally fine fibers, yield a lightweight and breathable material. This technological innovation elevates comfort levels while concurrently delivering effective UV protection.

Developing microfiber technologies necessitates precision in controlling fiber diameter and refining fabric construction to meticulously balance breathability and UV protection.

Hybrid Fabrics: The amalgamation of different fabrics or layers with diverse properties allows for a synergistic approach. For instance, a densely woven outer layer may confer UV protection, while a breathable inner layer augments overall comfort.

Executing strategic layering or hybrid construction demands careful consideration to seamlessly integrate components, ensuring the collective fabric optimally delivers on both UV protection and breathability.

Testing and Quality Control: Rigorous testing, encompassing standardized methods like UPF testing for UV protection and air permeability testing for breathability, stands as a cornerstone.

Stringent quality control measures serve to validate that fabrics consistently meet predefined standards for both UV protection and breathability, assuring uniform performance across production batches.

Consumer Feedback: The active solicitation of feedback from end-users through avenues such as surveys, focus groups, and comprehensive product testing constitutes an indispensable practice.

Iterative design processes, fueled by insights gleaned from consumer experiences, enable continuous refinement and adaptation of sunscreen fabrics to evolving preferences and real-world usage scenarios.

Environmental Considerations: The nuanced comprehension of the environmental conditions wherein sunscreen fabrics will be deployed becomes imperative. Factors such as outdoor activities, climate variations, and specific applications exert pronounced influence on the requisite balance.

Tailoring fabrics to environmental demands involves a meticulous consideration of variables such as temperature, humidity, and potential exposure to water, ensuring that the fabric's performance aligns seamlessly with the intended use cases.

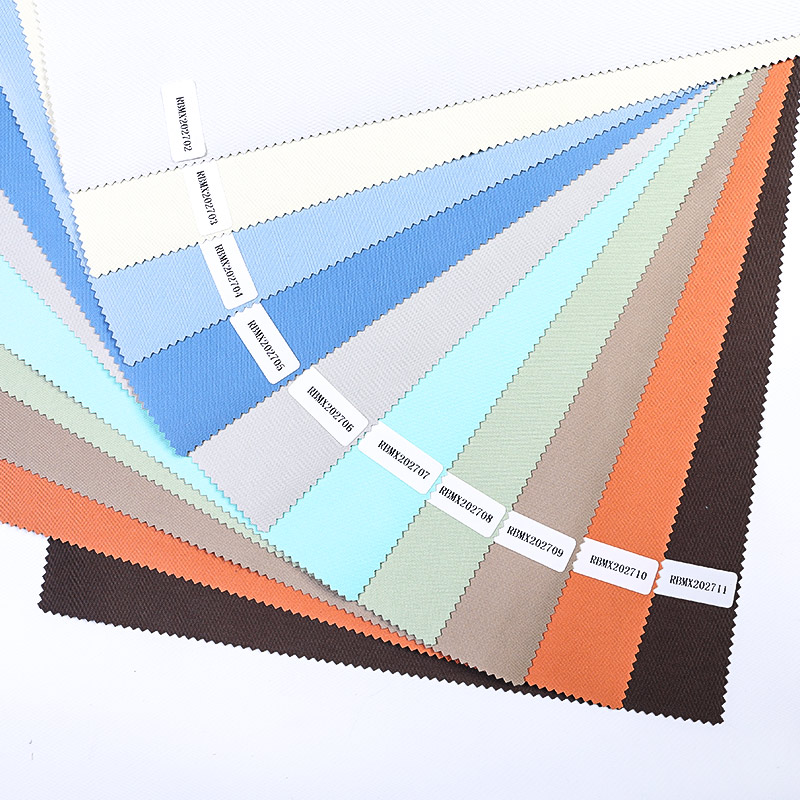

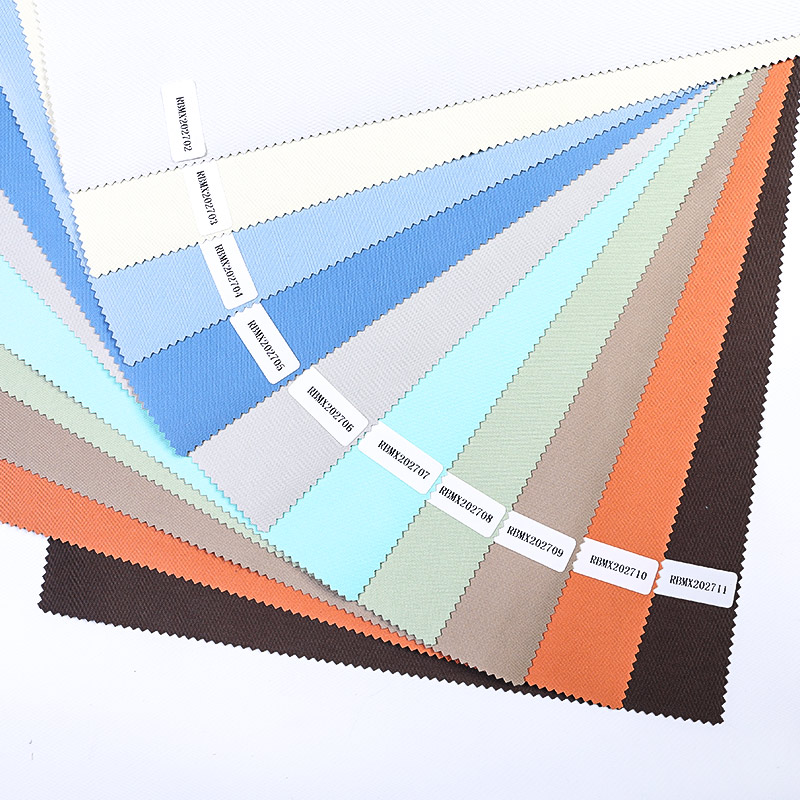

RBMX2027

RBMX2027

EN

EN  英语

英语 中文简体

中文简体